What is a Material Requisition?

Requisition reconciliation in accounting is the process by which two sets of records are compared for accuracy, completeness, and consistency. Under generally accepted accounting principles (GAAP), the required double-entry accounting method helps to pinpoint when and where errors exist. In this example, no errors or omissions were found, so a purchase order was created. The purchase order lists the specifics of the order, such as the product type and the quantity needed. Easily gather borrower details, track equipment specifics, and set clear terms and conditions. Crafted for easy risk assessment, this form template empowers you to identify and manage potential challenges across various business aspects.

Company

Quickly evaluate the likelihood and impact of strategic, operational, and compliance risks, and choose appropriate mitigation actions. Streamline your capital expenditure review process with our easy-to-use template. Effortlessly collect and review project details, financial breakdowns, and justifications in one place. Effortlessly capture the essence of your board meetings with our easy-to-use Board Meeting Minutes Submission Form. Simplify the process of recording discussions, decisions, and action items, ensuring accuracy and accountability.

Requester Information

Identifying inefficiencies in the requisition phase of construction planning is the first step to improving the process. Chartered accountant Michael Brown is the founder and CEO of Double Entry Bookkeeping. He has worked as an accountant and consultant for more than 25 years and has built financial models for all types of industries.

- On completion the material costs can be transferred to the job cost record template.

- The forms generally also include the signature of the individual fulfilling the request and the date completed.

- However, it can go off the rails quickly if you don’t have clean processes in place, leading to miscommunication and wasted time and money.

- Easily track inventory, control costs, and ensure authorization for all material requests.

- Automation allows staff to be reallocated to more critical work and saves time.

Related AccountingTools Course

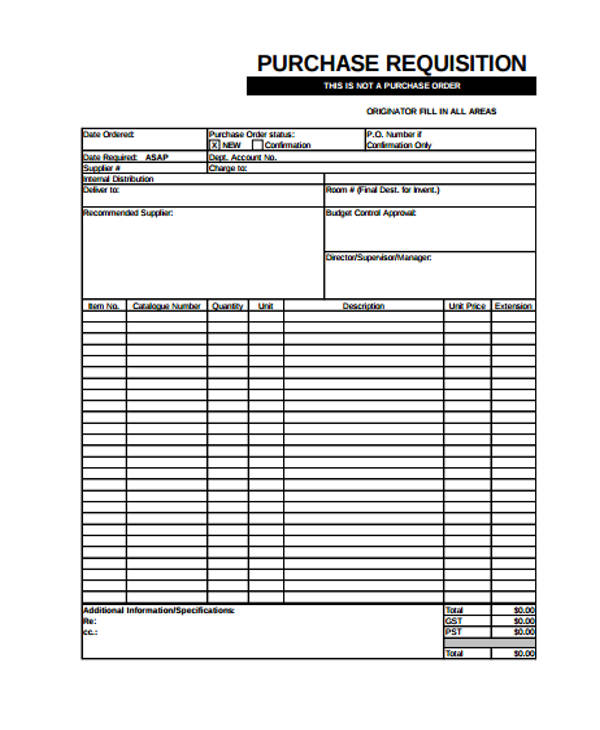

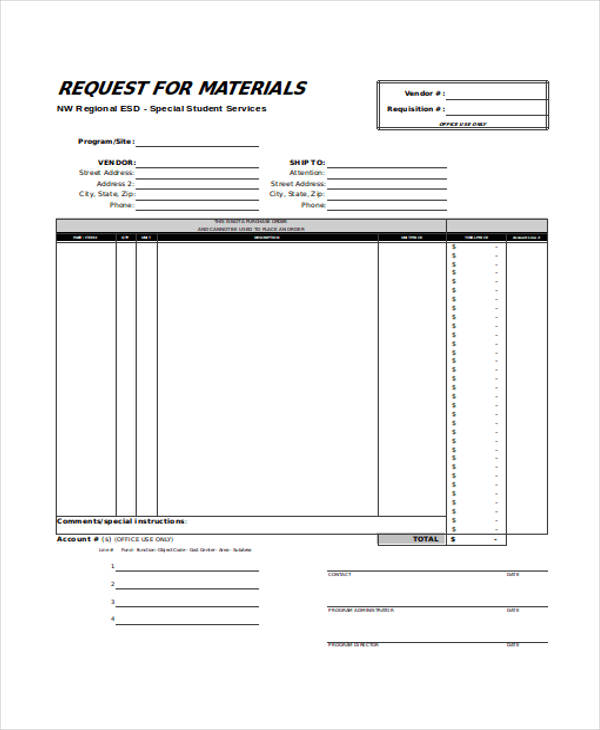

Some organizations may refer to a material requisition form as a purchase requisition form, however, there are some differences. A purchase requisition form can be used for any type of purchase, while the material form is only used throughout the production process. This formalized process ensures that all material requests are properly tracked and authorized, providing a mechanism for effective budget control and inventory management. It’s a basic yet important part of managing a company’s resources efficiently. A Material Requisition Form, often simply called a requisition form, is a document used within a company to formally request the purchase of specific goods, materials, or services. This form is typically used as part of a business’s internal control system to ensure that purchases are authorized, necessary, and within the company’s budget.

Too many companies are still dealing with manual material requisition processes. Not only do these processes slow down production, but they are fraught with other problems. As part of the production process, we need to order many different materials. Coordinating these tasks involves finance and operations staff, managers, warehouse staff, and line operators responsible for timely product creation.

Use this free template to enhance safety, improve hazard tracking, and ensure a secure work environment. Streamline your process with our user-friendly M&A Inquiry Form template! Gather key details about your company, objectives, and criteria for potential partners effortlessly. This form small business general ledger accounts examples and more covers everything from company history to legal considerations. Kickstart your business’s sustainability journey with our user-friendly Business Sustainability Checklist! This handy template covers key areas like energy efficiency, waste management, employee well-being, and more.

Countless roadblocks can obstruct the requisition process depending on the job, your team, and how you operate. Here are some of the most common mistakes to look for and what to do about them. The material requisition slip is available for download in PDF format by following the link below. Once a Material Requisition Form is completed and approved, it’s typically forwarded to the company’s purchasing department, which will then initiate the purchase order process with the supplier.

The production manager generally fills out the materials requisition form and delivers it to either the materials or storage department where all the raw materials are located. Then, the materials manager approves the request and has the raw materials moved from the storage area to the production floor. These documents play a pivotal role in streamlining procurement processes, facilitating clear communication between departments, and ensuring timely access to necessary materials. By adhering to the guidelines and examples provided, organizations can optimize their material requisition practices, contributing to overall operational efficiency and productivity. A typical materials requisition form has the job number, date of request, material description, quantity, and proper management signatures. Depending on the size of the company, request forms are filled out weekly, daily, or even hourly.